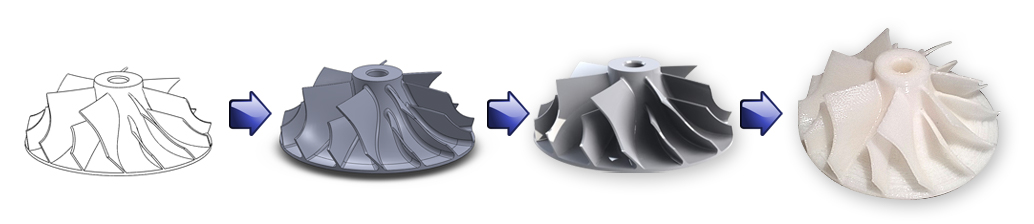

We have the capacity to produce rapid 3D prototype models for product development, visualising concepts, or testing a design/assembly at a fraction of the cost of a one-off machined sample.

3D printing greatly reduces the cost and development time by ensuring your product is right first time before committing to a production run.

Our 3D printer (Markforged X7™) is a turnkey industrial carbon fiber 3D printer, which will take a CAD drawing of your product and turn it into a real sample that you can touch, test, assemble, evaluate or modify. Built with precision-machined hardware, advanced sensors, and unique software drive leading edge accuracy and reliability, our 3D printer offers micron-level laser scanning for closed-loop calibration, reliably yielding parts with high repeatability and near-perfect surface finish.

For printing material options, we keep micro carbon fiber filled nylon in stock. It yields accurate parts with near flawless surface finish, and offers high strength, toughness, and chemical resistance when printed alone. Need something different? Don’t worry, other print materials are available, just simply ask!